Products

Venturi scrubbers

1. Type of technology

Wet collection.

2. Contaminants which can be removed

Dusts and water soluble substances after checking the concentrations.

3. Emission limits possible

As regards removal of dusts, collection efficiencies over 96% can be achieved without difficulty.

Efficiencies concerning removal of water soluble substances are generally modest.

4. Description of the equipment and/or process

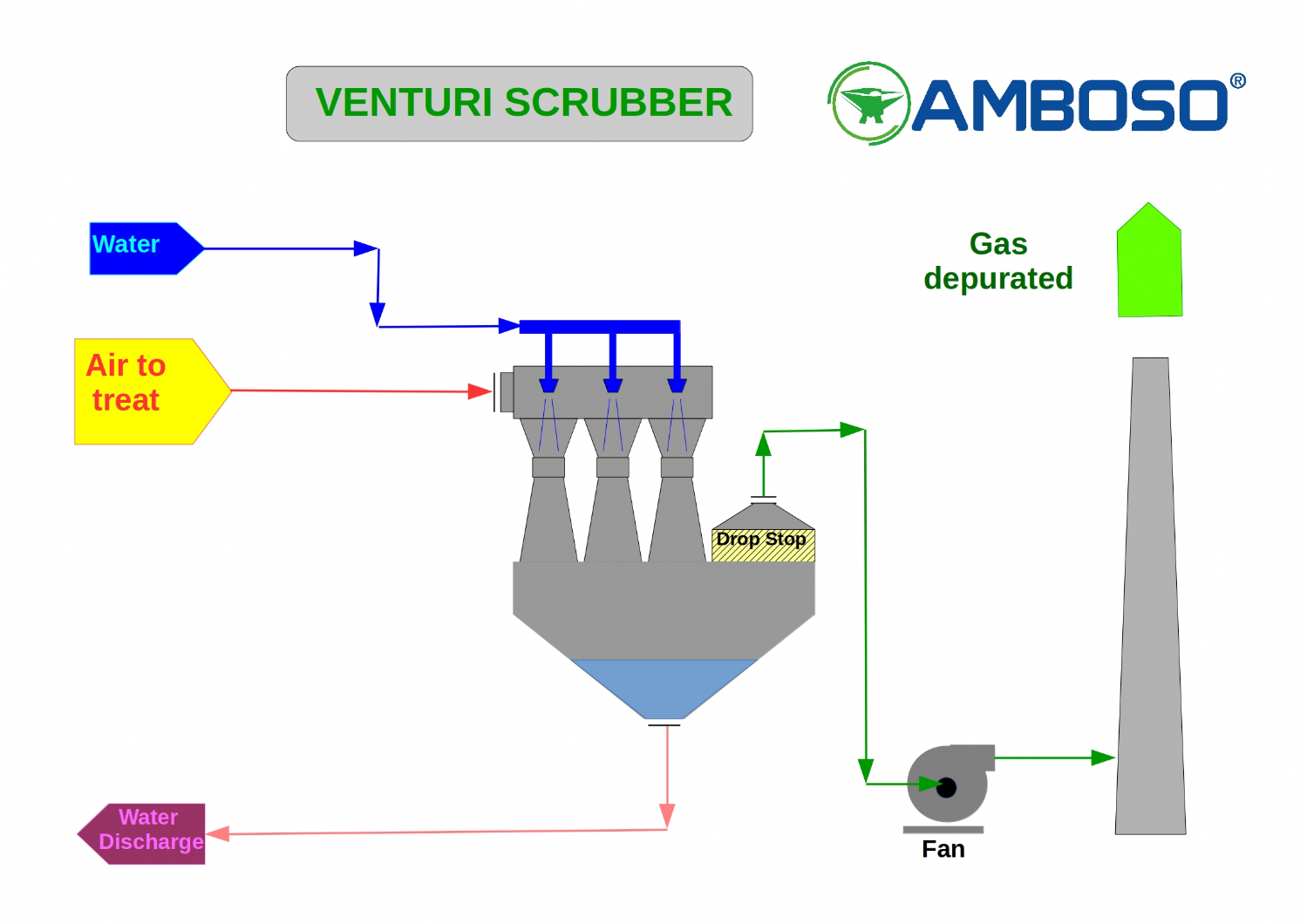

Venturi scrubbers are based on the principle of atomization of the scrubbing liquid from the same gaseous flow containing the contaminant to be removed, which is forced to flow through one or more annular orifices, thus increasing its face velocity at that point by n times, and entraining the atomized water in virtue of the well known Venturi effect.

During this phase there is the interaction between gas and liquid which causes the “capture” of the solid particles. This type of wet collector is horizontal in arrangement, therefore it takes up very more less space compared to the classic scrubbing tower.

With due consideration for all the intrinsic limits of such system, it represents, however, the optimum solution and a good compromise between quality/price in all those cases where there is limited space available and when the gaseous flow contains a large quantity of solid particles, better if of high specific gravity.

The scrubber consists of a series of standard elements, identical to each other, and each able to handle an air flow rate of 2500 m3/h.

Hence it is a modular structure which can consists of a variable number of elements, from one up to twenty venturis (or more).

The level of water used remains constant thanks to the use of an automatic level control. In order to ensure that residual emission values fall within the regulatory limits, also for this type of plant it is vitally important to observe certain design parameters on upstream side, such as:

- air flow rate

- velocity of the flow at the air/water interaction point (which normally exceeds 60 mt x s-1)

- correct shape of the Venturi

- water level

- height of the bell housing with respect to the baffle, which, in all models, should be vertically adjustable in order to achieve maximum performance in contaminant removal.

Plants of this type have the advantage of a decidedly more favourable price compared to scrubbing towers but, owing to the high pressure drops, they require more energy.

Generally speaking plants are available ranging from a minimum of 2500 m3/h (one Venturi) and a maximum of 50000 m3/h (20 Venturis). However provision can be made for higher flow rate on Request.

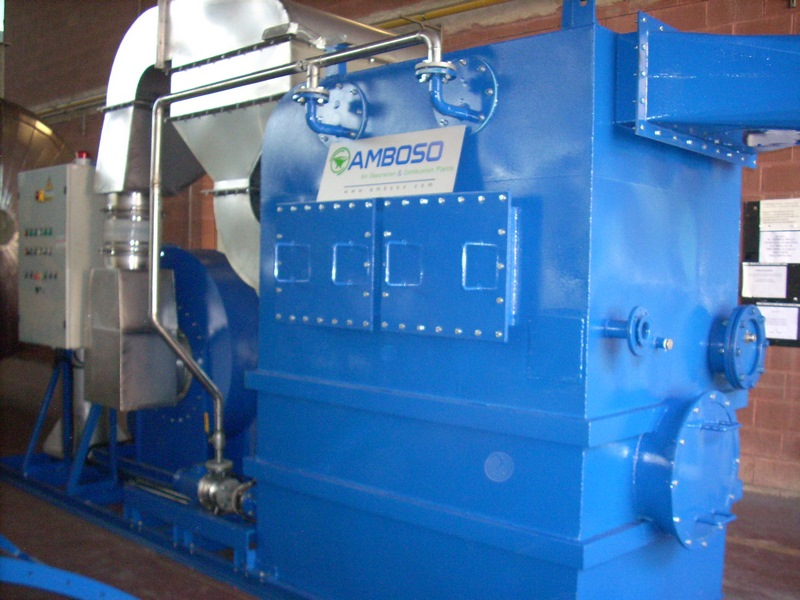

Depending on the contaminant to be removed (if in dust-form or acidic) the construction can be of carbon steel sheet with double coat of epoxy paint or else of stainless steel likewise with protective polyester coating. When the gas flow to be handled contains solid particulate, also of minimum particle size, the adoption of a sludge decanter is always recommended. Obviously also the type of plant requires subsequent treatment of the saturated water collected in the tank below.

As stated previously, with respect to the vertical version, higher pressure drops are involved (owing to the Venturi effect) and normally for the same air flow rate, an increase in motor power rating of 30% - 50% is applied.

Actually, thanks to the straightforward design of the scrubber, investment and running costs are rather reduced; likewise for the maintenance costs.